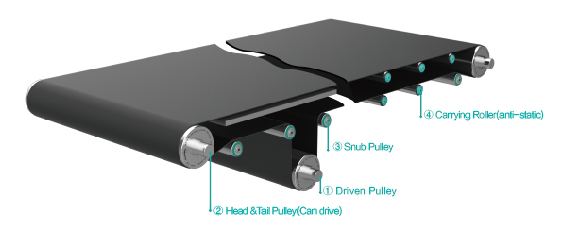

① Driven Pulley:

Main driving component for centre drive belt conveyors:

Select BP-D series pulley (rotating shaft).

② Head & Tail Pulley:

Installed at each end of a belt conveyor according to the different drive type and structure:

a、Centre drive:

Change the belt direction: Select BP-R series pulley (fixed shaft) or DP-D series pulley

(rotating shaft)

b、Head or Tail drive:

Drive Pulley: Select BP-D series pulley (rotating shaft)

Idler Pulley: Select BP-R series pulley (fixed shaft) or BP-D series pulley (rotating shaft).

③ Snub Pulley:

Used to increase the belt wrap angle for the driven pulley, tension and tracking the belt.

Select BP-R series pulley (fixed shaft) or 1200 series conveyor roller.

Be careful about the belt tensionning and siding focce when using as redirection & tensioning.

④ Carrying Roller:

Used to support the belt, simplify structure and reduce friction:

Select 1200 series conveyor roller.

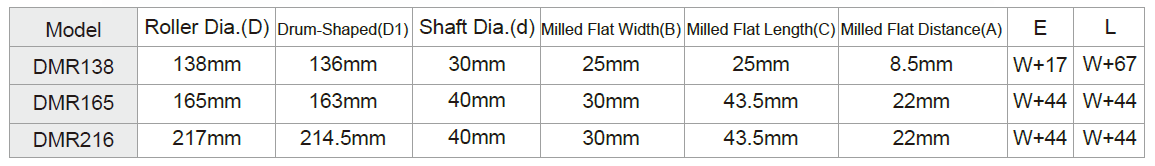

Bacis Parameters

| Roller Model | DMR138 | DMR165 | DMR216 |

| Rated Voltage | AC 3X380V(±10%) / 50Hz | AC 3X380V~418V / 50Hz |

| Rated Power | 1.82kW | 2.55kW |

| Rated Current | 3.6A | 4.9A |

| Length Range | 500~1100mm | 800~1400mm |

| Working Temperature | -5~40℃ | -10~40℃ |

| Ambient Humidity | 10~90%RH(Non-condensation) |

| IP Rating | IP54 |

Performance Parameters

| Product Model | DMR138 | DMR165 | DMR216 |

| Rated Torque | 61N·m | 174N·m | 278N·m |

| Belt Pull | 884N | 2109N | 2574N |

| Current Range | 30~90m/min | 30~60m/min |

| Load Capacity | 43kg/m | 60kg/m |

| Belt Conveyor Length | ≤6m | ≤9m | ≤12m |

| Maximum Belt Tension | 800kg |

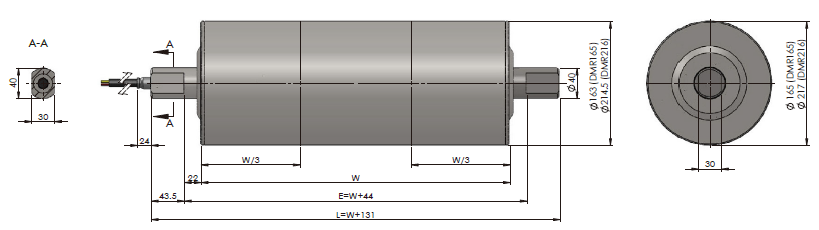

Product Dimensions (Zinc Plated)

•Easy setting of direction, speed, acceleration,and deceleration.

•Standard equipped with an assistant-type intelligent LCD keyboard

•Comprehensive protection functions including short circuit, phase loss, overload, overheat, etc.

•Detachable LCD keyboard for flexible and convenient external use.

•Digital IO, bus communication (RS485, CANOPEN) And other control methods.

Drive Technical Data

| Rated Voltage | 3X380VAC 50-60Hz |

| Rated Power | 2.2kW |

| Rated Current | 5.6A |

Noise Level | 40dB |

Drive Application Environment

| Operating Temperature | -15~55℃ |

| Relative Humidity | 5~95%RH (non-condensation) |

| Vibration | Maximum 1mm (0.04in.) (5-13.2Hz), Maximum 7m/s2 (23ft/s2) (13.2-100Hz) sinusoidal |

| Altitude | 0-2000m (for TN, TT, IT grounding systems) |

| Installation Method | Thread Fixed Installation |