English

中文

English

Europe

Welcome to Damon Industry Website

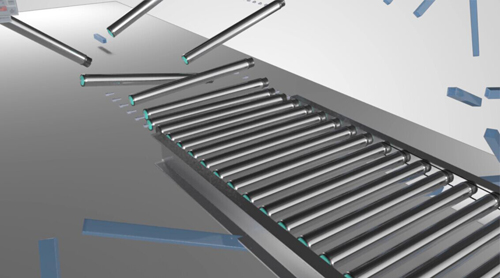

Nowadays, MDR conveying is more and more common with more and more applications. Especially the development of the express industry is faster and faster. Double Eleven Carnival is a household shopping festival. In 2015, Tmall double eleven sales totaled 91.217 billion yuan and 118 billion yuan in 2016. At this time of the year, it is a big challenge for the express logistics industry. Pressure on logistics sorting center is enormous. The users put forward higher and higher requirements on roller conveying line, part of the entire conveying system. Conveying parts suppliers are also facing increasing challenges.

Owing to its high power, AC motor is used as the driving source on the traditional roller conveying line with too many driven rollers. Due to so many driven rollers, there are a lot of goods on the zone driven by each motor. If the goods need to be controlled on the zone by accumulation, accumulation driven rollers and mechanical barriers are needed while the motor continues to keep running, making the goods move forward, which will make the front and back goods collide. It is bad for the sorting on latter zone.

The DC 24V electric roller is the core of the roller conveying line. As a power source for conveying, it is required to be more stable, more efficient and more intelligent. At present, the mode of ZPA (Zero Pressure Accumulation) is accepted gradually.

Then what is ZPA?

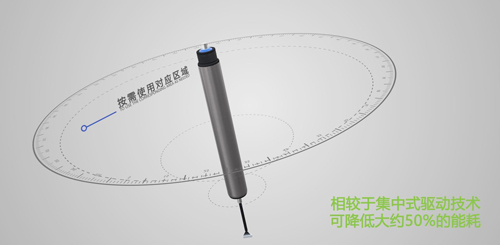

The distributed control is adopted in the ZPA delivery of MDR to divide the zone driven by each MDR with the length of single goods for reference. Each zone will have photoelectric sensors to locate the goods. The electric roller will run when necessary and stop running when the goods are accumulated or not loaded. If the goods have been accumulated at the end of the MDR zone, goods will be parked in order at its upstream zone without making the front and back goods collide.

We can see that there are several characteristics of ZPA:

1. Energy saving: MDR can start and stop frequently as required while the ordinary AC motor can't start and stop frequently so that it needs continuous operation. After comparing with the normal motor, we can find that MDR can save more energy.

2. Reduce the probability of the goods damage: when they are conveyed by zero pressure product function, the goods will not collide and squeeze.

3. Low noise: The noise of the driven roller and the noise of the AC motor are greater than that of MDR.

4. Space saving: the installation of AC motor needs more space.

Of course, all the above is only about simple ZPA function. Damon Industry assorted driven card has expanded many functions on basis of original ZPA function to achieve more intelligent conveying.

Data Tracking Function

When the goods enter the roller conveyor line, you can write the number of goods into the driven card. The goods are transmitted with this number. The adjacent roller conveyor zone will have data exchange. While the goods are transmitted, so is the number data between zones.

Pre-decelerating Function

On the high-speed roller conveyor line, we always have a problem - the brake distance is too long. This is because the goods transmission speed is so fast that the inertia is powerful. Therefore, on the basis of ZPA function, the pre-decelerating function is added. The principle is to pre-decelerate and reduce the inertia before the goods arrive at the designated position.

Block Error Recovery

When the smaller goods are transmitted, the goods will be stuck between rollers (roller gap is too large). After block error recovery function is turned on, the pulserollers in the block zone will operate in reverse direction, trying to “pull” the goods out from the roller gap to solve the block.

Damon Industry IQZonz and Conveylinx series driven cards have built-in ZPA function, which reduces the customer's own programming time and increase the stability. Conveylinx series driven card has many extensions, embedded in the original ZPA function in module form. The customer can choose to use or shut down according to the actual situation, which is more convenient for customers.

Damon Industry DC24V MDR can bring change and innovation for the conveying line and help e-commerce cope with greater challenges. At present, Damon Industry DC24V MDR has been applied in Suning, Tmall, Vipshop and other major e-commerce and logistics industry to solve the transmission problems and logistics pressure for customers.