English

中文

English

Europe

Welcome to Damon Industry Website

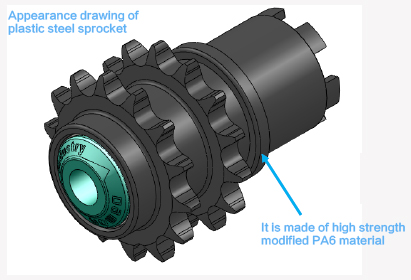

When thinking about sprocket transport, the first thing that comes to someone’s mind is the steel sprocket, often overlooking the plastic steel sprocket. It is true that the steel sprocket has more advantages in terms of heavy-duty conveying and specification models, while plastic steel sprocket does not seem “very reliable”.

For instance: Can the impact resistance of the plastic steel sprocket meet customer demands? Can be stability and longevity guaranteed in case of a plastic steel sprocket that is used for a long time?

Let’s do justice to the plastic steel sprocket by showing you the actual experimental data:

Experiment 1: Impact resistance test

Experimental conditions: 160kg load

Experimental method: start and stop 110,000 times

Experimental results: no damage or deformation after continuous start and stop

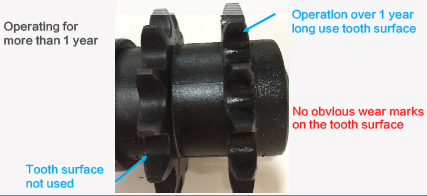

Experiment 1: Impact resistance test

Experimental conditions: 160kg load

Experimental method: number of products delivered: 450,000 times (24 hours of operation)

Experimental results: The gear shape was intact, no creep occurred, and the tooth surface did not wear significantly.

In conclusion, we believe that the performance of the plastic steel sprocket is relatively stable and reliable when conveying less than or equal to 160KG.

Compared to the steel sprocket in the same working conditions, the plastic steel sprocket has the following advantages:

1. Delivery time advantage

The delivery time of the basic plastic sprocket roller is about 4-5 days faster than that of the steel sprocket roller.

2. Cost advantage

Generally, the plastic steel sprocket roller has lower procurement costs than the steel sprocket roller with the same configuration.

3. Maintenance advantages

There is no need to regularly apply oil on the regular sprocket to prevent rust and to ensure lubrication.

4. Noise advantage

The bearing assembly consisting of a precision ball bearing, plastic inner and outer case and a plastic steel sprocket has a much lower operating noise than one comprising a steel sprocket roller.

5. Structural design advantage

If the drive ring from inside a plastic steel sprocket roller is removed, it becomes a plastic steel sprocket accumulation roller (it can be converted into this type of roller), which is convenient for any temporary changes in the customer’s design line structure.

However, we can talk about the above mentioned advantages if the plastic steel sprocket roller operates under tolerable conditions, a fact that cannot be ignored.

Although our plastic steel sprocket is similar in appearance with the steel sprocket so it can be easily ignored, its advantages are obvious.