English

中文

English

Europe

Welcome to Damon Industry Website

In mid-April 2019, Damon Industry held a "ZAM Tube Roller" conference at the LogiMAT China Exhibition site, which introduced ZAM tubes into the logistics conveying roller industry to enhance customer value. Up to now, three months have passed, has the promotion of ZAM tubes achieved the desired results? How about the acceptability of our customers? Let us witness together!

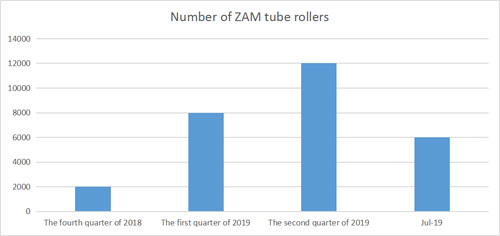

I. The quantity of ZAM tube roller used by customers grows steadily

Damon Industry has been sticking to the principle of seeking improvement in stability. Since the release of ZAM tube, customer acceptance has gradually increased, so does the number of ZAM tube rollers. With the increase of customer acceptance, the number of ZAM tube rollers increased rapidly in June and July this year.

II. Customers highly recognize the rust prevention capability of ZAM tube

Since its promotion, there have been two customer complaints about product surface problems. The main reason is that ZAM tube rollers and directly galvanized rollers are used on the same line, so that two different surface states are displayed. However, there is no complaint about the failure of surface rust prevention. Compared with directly galvanized rollers, the surface quality defect of ZAM tube has decreased significantly.

So why ZAM tube can be promoted so rapidly and gain extensive customer acceptance?

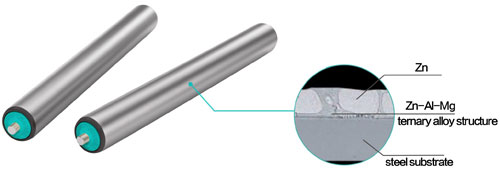

Firstly, the anti-corrosion property of ZAM material is outstanding. Compared with galvanized plate, its anti-corrosion property will be increased from several to ten times by increasing the proportion of Al and Mg in a certain range. ZAM tube roller has excellent corrosion resistance, which can easily solve the problem of surface rusting for customers.

On the basis of outstanding rust prevention, the surface consistency of ZAM tube roller has also been highly evaluated. The ZAM tube is matte and dark, so there is no reflected light in use, which eliminates light pollution and gains good reputation from the terminal.

A customer with many years of in-depth cooperation with Damon Industry said that "Since October 2018, we have started to use ZAM tube rollers in a large hospital in Guangzhou and other projects. After more than half a year's use, we found that this material not only guarantees anti-rust performance, but also is more environmentally friendly. It can also shorten the delivery cycle, especially suitable for the wet spot in the middle of the second floor. At present, all the products in use are running very well. Therefore, it is believed that the promotion of ZAM material by Damon Industry will be a very important breakthrough and optimization for the whole industry.

ZAM is a kind of hot-dip galvanizing. In the logistics assembly industry, hot-dip galvanizing has been used in the manufacture of shelves, conveyor supports and guardrails for its advantages of simple process, stable quality and strong metal texture enjoy higher and higher popularity. Damon Industry roller also plays an active and important role in this change. Here, we are also very grateful for our clients' acceptance and recognition.