English

中文

English

Europe

Welcome to Damon Industry Website

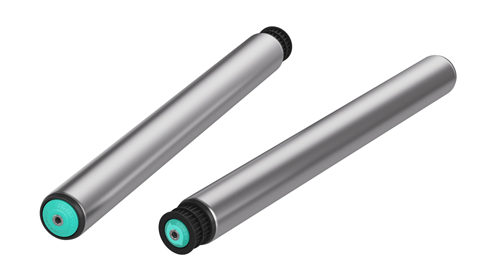

During the Golden October with the floating aroma of osmanthus blooms, CeMAT ASIA 2017 was held in Shanghai New International Expo Centre as scheduled. As the earliest and most professional conveyor roller manufacturer in China, Damon Industry participated in this international logistics exhibition with enthusiasm as always. After a long period of market information collection, Customer Requirement Survey and technical design, Damon Industry revealed a new roller series – 2280 series Timing belt pulley conveyor roller at CeMAT.

With the rapid development of the logistics industry in recent years and further perfection of related logistics elements, logistics equipment industry manifests various requirements on informationization specialization and intellectualization. As the core part of logistics conveying equipment components, the conveyor roller is facing new problems and challenges.

The traditional O-belt drive in conveying roller has the problems of low load capacity and low conveying efficiency. Although the poly-vee pulley can overcome the above defects, its mild wear with “ash drop” in use is inevitable due to the principle of friction drive. The poly-vee pulley can’t be operated on the severe environmental condition such as in the clean-room. When it comes into contact with water, it is easy to skid and its load capacity will decline sharply while the chain drive has some restrictions such as noise, speed and oil contamination.

Our solutions are: The rollers are connected by the Timing belt. The belt and the pulley are meshed to drive without relative sliding. After several months, it has passed various critical tests of key function and performance and durability test of over 500,000 cycles.

Compared with the traditional conveying, the roller has the following characteristics:

· It has greater conveying capacity, which is suitable for medium and heavy load conveying.

· It has compact structure and simple design without tensioning.

· It is more efficient without slip synchronous in conveying.

· The T5 tooth shape design is suitable for the roller conveyer with higher versatile.

· Its positioning is precise with the use of MDR to meet the application requirements of the load section.

· It is suitable for clean room and other harsh environment with the use of PU Timing belt.

· Compared with traditional belt drive, it is waterproof (no skidding) and has the ability to work in a certain bad environment.

· It needs no lubrication with easy maintenance.

Damon Industry 2280 series Timing belt pulley conveyor roller integrates the characteristics of traditional belt drive and chain drive, solves the problems which belt drive and chain drive encounter in the practical application and meets the customers’ demands on load, efficiency, stability, energy saving and versatility.

Customer demand is the driving force of our progress. Customers’ satisfaction is our goal. Damon Industry will uphold the spirit of innovation with our customers all the way forward!