English

中文

English

Europe

Welcome to Damon Industry Website

At the beginning of this year, Damon Industry launched a new generation of domestically produced box-type electric rollers — the DMD series. Thanks to their impressive performance and strong reliability, the series has rapidly expanded in the domestic market. Currently, it has been successfully applied in over 100 projects.

At the same time, to ensure the smooth implementation of the new product on-site and to quickly resolve various customer issues, Damon Industry's Product and Technology Department assigned experienced application engineers to form an on-site technical team. This team proactively conducts inspections on key projects and addresses any on-site reported anomalies.

In this article, we will follow the perspective of an application engineer to experience a typical on-site technical service process. See how they respond quickly, pinpoint issues accurately, and efficiently resolve on-site problems to ensure smooth and efficient production on the customer's new energy production line.

Quick response

In the heat of July, we received feedback from a customer regarding an abnormal operating condition in a new energy project. We immediately activated our rapid response mechanism and began coordinating with the customer.

Upon further investigation, it became clear that the core issue reported was the insufficient load-bearing capacity of the electric rollers during high-load conveying, which in turn affected the efficiency of battery module transport. After an initial round of troubleshooting via phone and video calls with the customer's on-site engineers, my colleague Mr. Bai and I set off to conduct an on-site inspection in a southern province.

Close to the scene

The next day, upon arrival at the site, the customer’s project manager immediately took us to the smart production workshop of the new energy battery module line, where the reported issue had occurred. The battery modules were neatly stacked in bins and transported between workstations via a densely arranged electric roller conveyor system.

I couldn’t help but feel a mix of curiosity and doubt, and quietly asked my mentor, "These battery modules look bigger and heavier than before. Can our DMD series handle them?"

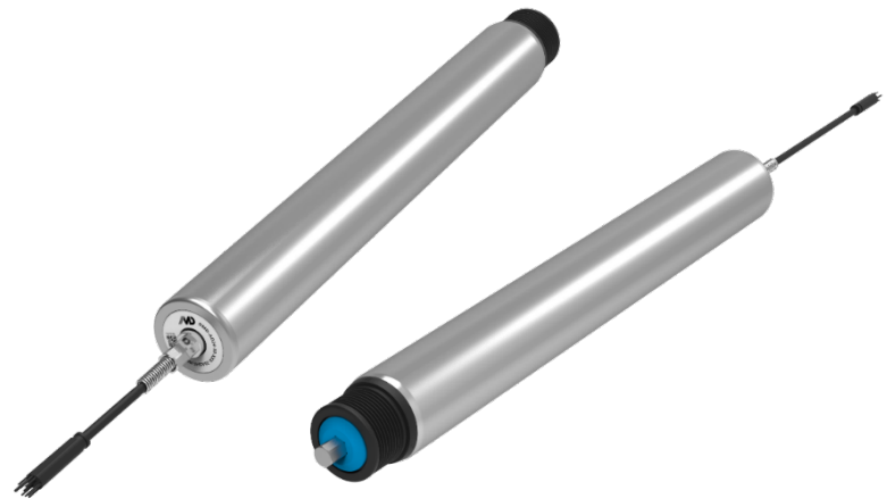

Walking alongside me, Mr. Bai explained, "Don’t be fooled by the appearance of our self-developed DMD series — it may look similar to other products, but a lot is going on under the hood. The new servo direct-drive motor structure improves motor efficiency and torque, while eliminating the losses caused by the gearbox. Moreover, the load capacity per roller has increased, and overall operational noise has been reduced."

As I listened carefully, I noticed that despite hundreds of rollers running simultaneously in the workshop, the noise level on the meter remained below 65 decibels.

Accurate diagnosis

After identifying the problematic workstation, we used a toolkit to diagnose the issue with the DMD electric rollers, following the principle of "checking the periphery before the core" step by step. After ruling out major interference factors, my mentor keenly noticed an abnormal specification in the cable supplying power to the drive card.

I immediately calculated the theoretically required minimum cable diameter based on the on-site operating conditions using the voltage drop formula: ΔU = I × (ρ × L / S). We confirmed that the abnormal load-carrying failure was caused by voltage drop issues: when the actual voltage cannot meet the rated operating voltage of the electric rollers (DC 24V ±10%), the roller torque cannot be fully exerted. After measuring the supply voltage at the problematic workstation, we verified that was the cause of the failure to carry the load.

Customized solutions

To address this issue, we collaborated with the on-site electrical control team to design a more reasonable and cost-effective cable layout tailored to the operational conditions of the smart production line. This solution was then delivered to the customer’s project manager. What made me proud and happy was that this efficient technical service not only successfully resolved the on-site problem but also, through professional theoretical analysis and data support, reassured the customer regarding project timelines and cost control. This fully reflects the work philosophy I have always upheld as a Damon Industry application engineer: "With professional expertise and passionate dedication, we build comprehensive product and technical support solutions for our clients' rollers."

At the time of writing this article, the engineer is already en route to another site. This is a typical snapshot of the daily life of Damon Industry application engineers. No matter how excellent the product, it requires strong implementation support. Therefore, we always adhere to the principle of "embracing professional knowledge and acting with passion’, applying expertise, keen insight, and efficient execution to embed the word “reliable” in every project and service, building a solid backbone for our customers’ smart conveying systems and continuously driving the flow of value.