English

中文

English

Europe

Welcome to Damon Industry Website

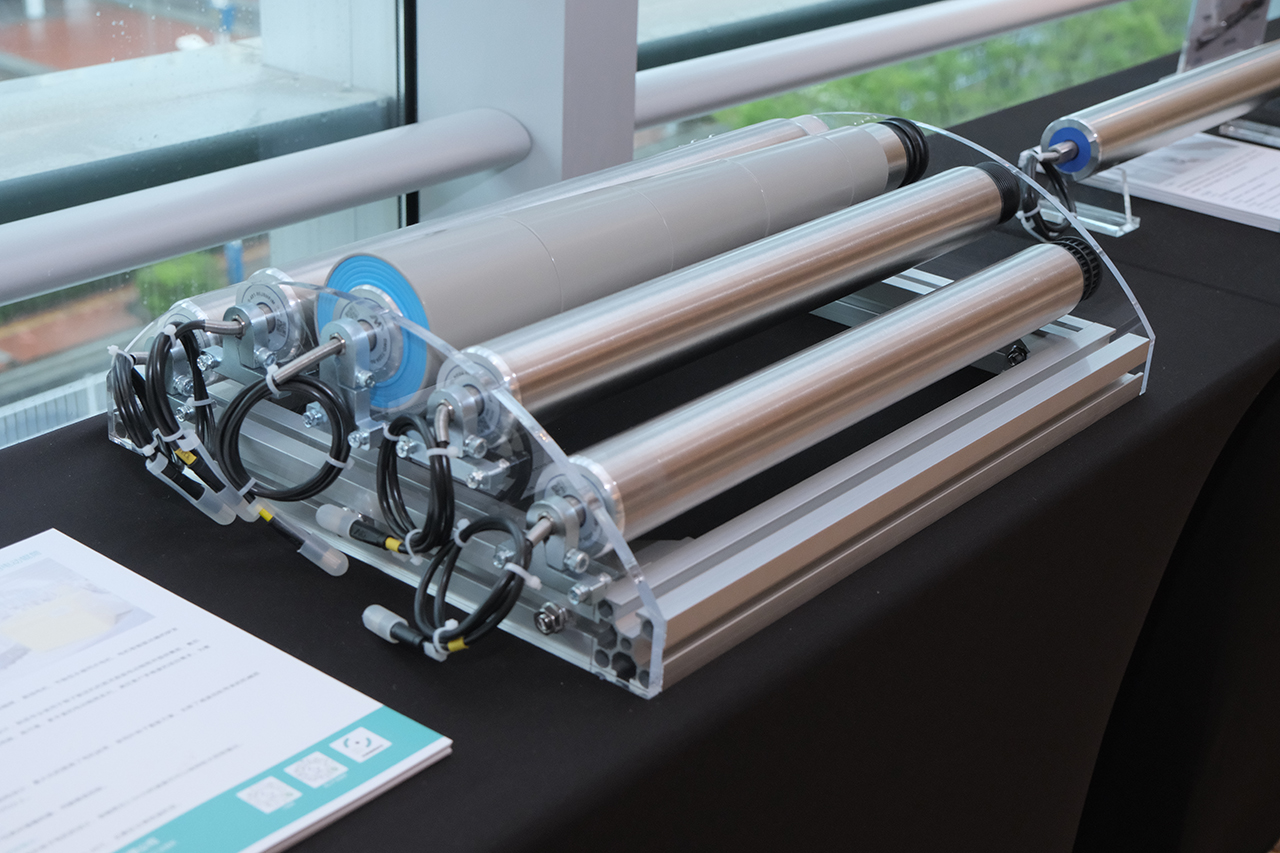

In early spring this March, Damon Industry collaborated with manufacturing enterprises in Beijing, Suzhou, and Guangzhou to host three spring product exchange events under the theme "A Fresh Start · Creating the Future Together." The events focused on key components in the field of conveying, where several new 2025 products were unveiled to over a hundred core clients. Among them, the newly developed DMD Series Motorized Rollers for Conveying, independently researched and developed by Damon, attracted widespread attention.

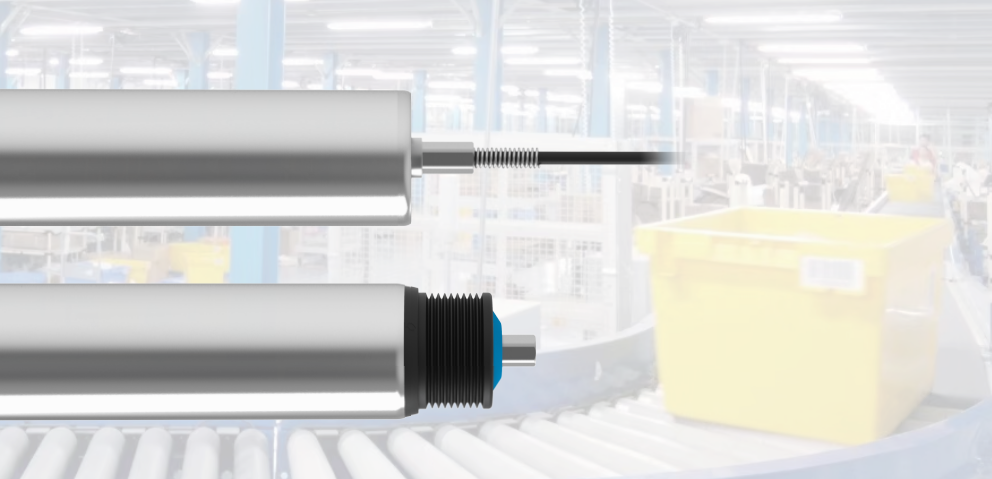

Amid the intense internal competition in the logistics equipment industry, the DMD Series Motorized Rollers for Conveying have redefined the technological boundaries of conveyor drive systems. Breaking away from the complex structure of traditional gear reduction mechanisms, they innovatively introduce direct drive motor technology, widely used in high-precision fields such as drones and wind power generation. This results in stronger performance, greater flexibility, and lower costs, helping the industry overcome the current bottleneck of excessive competition.

In this article, we will explain the technical and application features of the new “DMD Series Motorized Rollers for Conveying.”

Empowered by an innovative motor technology path and structural design, the DMD Series achieves three breakthroughs:

Enhanced Performance: With the same dimensions, the static load capacity is increased by over 50% compared to gear-driven motorized rollers. It handles the transport of heavy box-type items weighing up to 300 kg with ease.

Extended Lifespan: By eliminating complex components such as gearboxes, the number of parts is reduced by half, significantly lowering the theoretical failure rate over the product’s life cycle.

Quieter Operation: Operating noise is reduced to ambient noise levels, making it ideal for logistics environments where noise sensitivity is a concern.

Going a step further, Damon Industry has addressed key user pain points through targeted development and optimization, resulting in three unique advantages of the DMD Series:

Superior Braking Consistency

Equipped with a high-precision encoder, it enables servo-level precise control, effectively solving the common issue of inconsistent stopping positions for light and heavy items found in traditional motorized roller systems.

This makes the DMD Series an ideal solution for complex scenarios in industries such as electronics, pharmaceuticals, and apparel, where cargo varies in weight and precise positioning is required at transfer points.

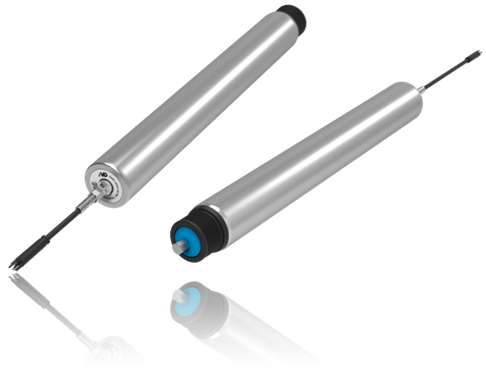

Wider Operating Temperature Range

Thanks to its new oil-free drive structure, the DMD Series motorized roller can operate in environments ranging from -20°C to 40°C.

This means that for colder regions in northern China or for cold storage and refrigeration projects, there is no longer a need to select special low-temperature models, simplifying the selection process and reducing costs.

Of course, even in standard environments, the DMD Series offers excellent tolerance to temperature variations.

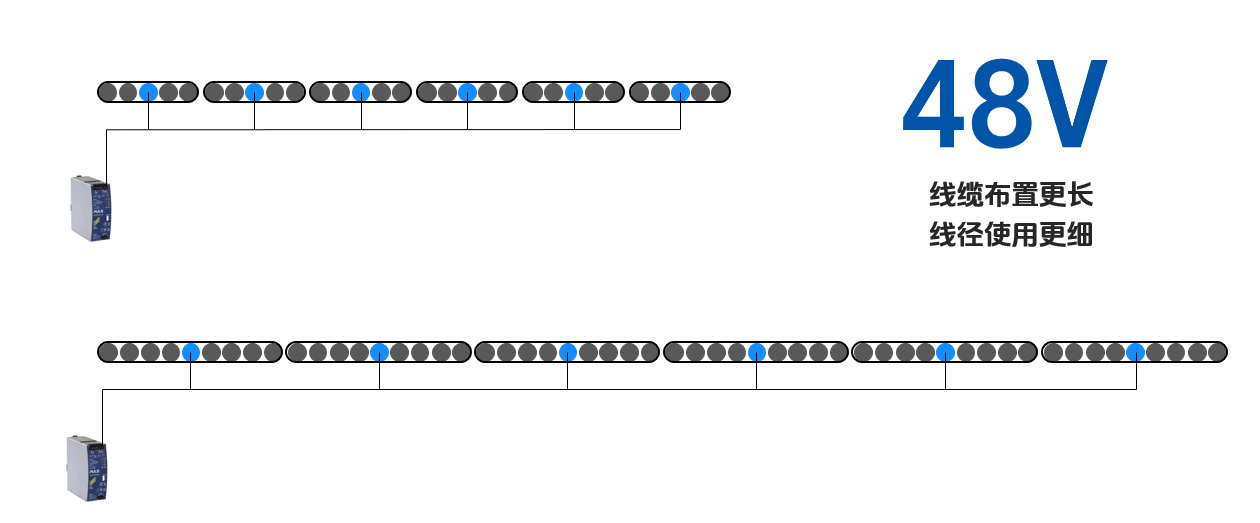

More Flexible Voltage Power Supply Options

The DMD Series supports both 24V and 48V dual power supply modes.

24V offers safety and stability, while 48V provides powerful performance, effectively addressing issues such as insufficient motor roller output power caused by long-distance wiring and voltage drop.

Additionally, the 48V option allows the motorized rollers to deliver higher torque under specific conditions, enabling a new level of load capacity.

The birth of the brand-new DMD Series motorized rollers for conveying is Damon Industry’s response to market demands, providing an additional choice for integrators and equipment suppliers.

Now, you can select between the DMD Series and the DPR Concord Series motorized rollers for box conveyors, based on your specific needs.

To eliminate usage barriers, the DMD Series and DPR Concord Series motorized rollers are fully compatible across all dimensions, including option logic, specification codes, installation methods, dimensions, and technical support, ensuring a seamless experience.

Damon Industry’s DMD Series Motorized Rollers for Conveying — Achieving a Win-Win in Cost and Performance through Technological Innovation. Direct-drive intelligence injects new, efficient, and lightweight momentum into the logistics equipment industry!

Stay tuned: We will be posting about two more new product series on our official account soon. Be sure to follow us!