English

中文

English

Europe

Welcome to Damon Industry Website

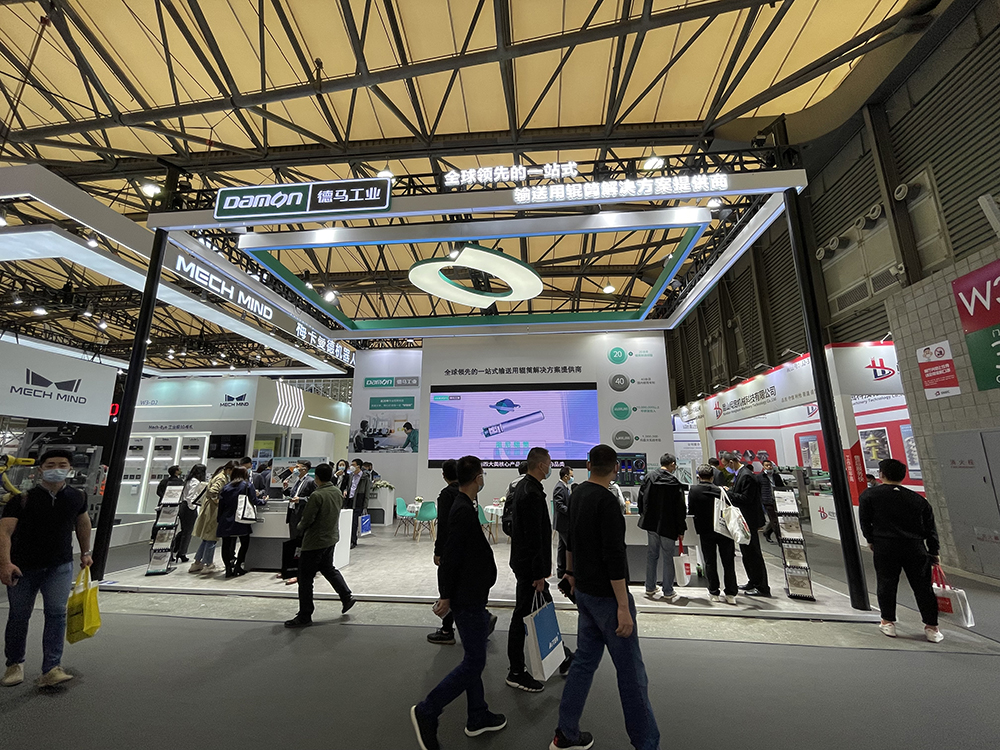

On October 26, 2021, the 22nd Asia International Logistics Technology and Transportation System Exhibition CeMAT ASIA opened at Shanghai New International Expo Centre. As one of the world's top suppliers of conveyor rollers, Damon Industry presented its new PU sleeve roller, tapered plastic steel sleeve roller and electric roller solutions, once again demonstrating its technological innovation strength to improve and match the upgrading needs of users, providing a strong impetus to better serve end-users.

According to Mr. Jin Chunhui, Zhejiang DAMON Industry Equipment Co., Ltd., Vice-General Manager, the PU sleeve rollers displayed during the exhibition have unique advantages, which can meet the needs of greater friction and lateral slip resistance, in diversified areas and goods-to-man picking areas with inclined roller conveyor arrangements. Compared to traditional polyurethane-coated rollers, PU sleeve rollers not only shorten the delivery time but also reduce material consumption, thus improving the return on investment of the roller.

The tapered plastic sleeve roller is an innovative product developed by Damon Industry to meet the requirements of low noise during high speed conveying and the need for rust prevention in certain industries where zinc and copper are prohibited. Its shaft core is made of plastic steel, which can better prevent rust and eliminate the high cost of rust prevention. The shuttle-shaped design perfectly eliminates the gap between the rollers and the frame. At the same time, the damping effect of the plastic steel material support meets the "high speed and low noise" operational needs. In addition, choosing the flexible shaft mounting method also makes users worry-free.

It is worth mentioning that Damon Industry has been actively responding to the two current goals of "carbon dioxide emissions" and "carbon neutrality". First of all, Damon Industry has developed DCB bearings for rollers, optimized the curvature of the bearing ball channel and its unique grease, and designed a special 2RZ sealing dust cover, which makes the whole roller more flexible, smooth and reliable for a long time. The energy consumption of using DCB bearings is 15% lower than that branded precision bearing rollers," Mr. Jin said to the journalist. At present, Damon Industry has reached 10 million rollers a year, with at least two bearings per roller. Therefore, Damon Industry can consume 212 kWh less electricity per day, which is equivalent to 85 tons less CO2 emissions per year.” Mr. Jin proudly said, "Secondly, our electric roller adopts DC brushless drive method, which can achieve the same transmission torque and save more energy than AC motor. We have also designed a unique energy-saving mode on the electric roller. After the electric roller is fully started and reaches full speed, the energy-saving ECO mode can be operated to maintain the cargo conveying status. With such a unique design, it is possible to save about 20% of energy consumption in the operation of the electric roller, and even 50% at the most efficient times.” Furthermore, we have a completely "zero" carbon emission product - the speed controller also often referred to as the brake roller. The product is often used in roller slide way where the cargo slides from high to low by gravity only, and the speed of the cargo can be flexibly controlled by the continuous acceleration process, so that the cargo slides at a safe speed, avoiding the damage caused by the impact of the cargo at too high a speed. Mr. Jin stressed that Damon Industry is committed to transforming itself into a solution provider, adhering to the roadmap of intelligent and green development, achieving optimization, efficiency, and innovation ability. Continuously innovating and improving to help users achieve value enhancement.

Talking about the current situation of the domestic and overseas development of Damon Industry Mr. Jin said: "Our logistics equipment has been very well controlled even in the face of the COVID-19 epidemic. As a supplier of conveying equipment components, first of all, Damon Industry will continue to focus on R&D investment in different industries and also expand its overseas business. At present, we already have six production bases overseas, and the growth of export trade this year will be close to 50%. Of course, the domestic market is also great, so we are very confident regarding the overall market situation in the future!"

In the future, we expect Damon Industry to make breakthroughs in innovation and green intelligent manufacturing, to be able to explore more niche markets, not only to be a leading company in the industry in terms of sales, but also to become a leading brand in technology solutions and services, and to help users create greater value!