English

中文

English

Europe

Welcome to Damon Industry Website

While people were just stepping into 2020, Xiao Li, the police liaison officer, was discussing with his girlfriend whether to apply for getting a certificate on the 2nd of February, a day of perfect symmetry. All of a sudden, an epidemic outbreak disrupted Mr. D’s work rhythm.

Based on the clues collected from the community, there were a few fugitive suspects from a specific area, who surrendered after the city was in lockdown but didn’t survive. Mr. D felt this complicated case like going on a holiday at the seaside and something to wait for.

Even so, he didn’t want to solve a case as tricky as the one from last month. If he wasn’t lucky, the unseen ghost would hover over the city for some time ...

【Case review】

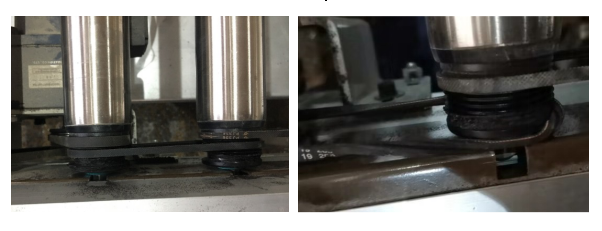

I wonder if our readers still remember the first part of the “Detective stories” – “Dark”. We presented the case of the V-ribbed pulley that melted, aka “the victim”, and also, we caught “the suspect”:

1) Overweight cargo;

2) Blockages or continuous running (hard accumulation);

3) Emergency start or emergency stop;

Since then, the "V-ribbed pulley meltdown incident occurred again somewhere”.

Having the previous experience, Mr. D boasted in front of the chief inspector that he will solve the case within a week. However, despite carrying on similar investigations, no clues were found at the scene.

The case investigation seemed to have reached a dead end. The need to find the suspects was haunting Mr. D just like “the ghost” of the previous case.

【The truth】

The truth revealed by sheer coincidence.

Let us understand the situation at the time:

The V-ribbed belt roller “victim” is located near the tilted wheel of the sorter’s mouth and it is usually connected to the motor. Although the already known possibilities had been ruled out, since it was "hot-melt", it was certain that the V-ribbed belt must have rubbed against the wheel.

During an on-site review, the assistant mistakenly placed the carton on the still-running line, and nearly hit Mr. D who was looking for clues. However, Mr. D heard an almost imperceptible noise when the carton passed through the tilted wheel sorter.

Speed!!!

In an instant, Mr. D figured out what happened.

【Scene reproduction】

With the help of the clues, we were able to reproduce the “case scene”.

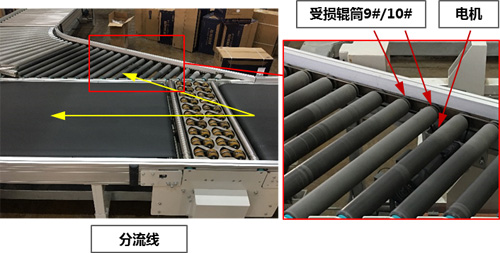

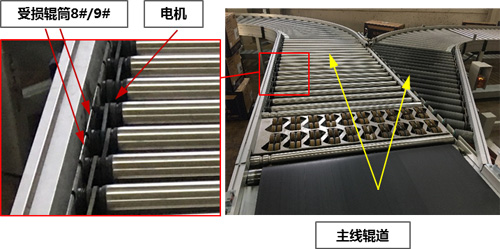

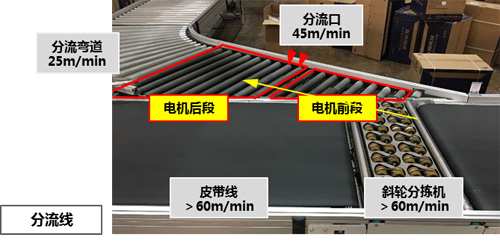

1) Take the diversion line as an example: when the carton enters the <diverting port> and then the <diverting curve> from the <tilted wheel sorter>, there is a significant difference in speed (from fast to slow). This is why we could hear the carton producing a disturbing noise.

2) When the carton moves from the fast zone to the slow zone, passive deceleration occurs. Restricted by the motor, the actual running speed of the roller does not change significantly. This means that the extra force generated (ie, the speed difference) is consumed by the belt (ie, the belt and the V-ribbed pulley produce a relative slip). Heat accumulates over time, creating conditions for hot-melt.

3) In addition, the first roller connected to the motor is driven by the 3PJ V-ribbed belt. The second roller is connected to the first roller by the 2PJ and the tension is not high. Since the force cannot be effectively transmitted to the third branch, the V-ribbed belt produces a relative slip on the pulley surface of the first and second roller This is the main reason why the damaged roller is usually located on the first branch or the second branch connected to the motor and the hot melt occurs on the 2PJ multi-ribbed belt.

【Post-scriptum】

What we learned from this case is that we have to pay attention to the maximum load, but also to the section connected to the power source and the frequency with which it starts and stops. It is also necessary to avoid obvious differences in speed between adjacent conveying sections.

Conveying speed, as one of the core elements in the design of the logistics system, should be given full consideration at the beginning of the process. Don't fall into the misunderstanding of "adding more and more water" during the debugging process.

But if it has already happened, then as a temporary solution, use a steel V-ribbed pulley + 4PJ V-ribbed belt design. In this way, you can reduce the " relative slip" situation to a certain extent.

Today, the ghost has disappeared, along with the epidemic and Mr. D is already looking forward to the next challenge.

See you next time!