English

中文

English

Europe

Welcome to Damon Industry Website

Time is passing quickly, along with the rapid development of logistics equipment industry. The question that once puzzled has been answered in time.

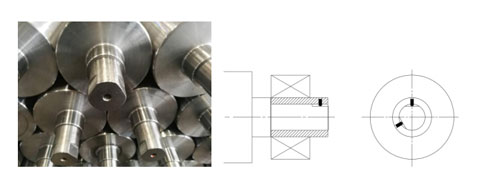

As an indispensable part of the belt conveyor, the driving roller faces a difficult problem. What is it? Grind the shaft!

What causes shaft grinding :

1. Metal characteristics: Although metal has high levels of hardness and strength, it has poor yielding, poor impact resistance and poor fatigue performance, so it can suffer damages from fatigue wear, abrasive wear and fretting wear.

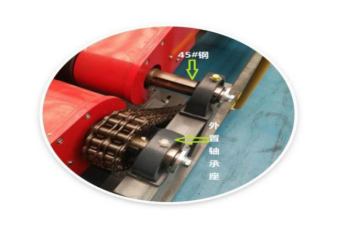

For example: the hardness of the bearing steel in the external bearing housing can usually reach above HRC60, and the 45# steel’s quenched and tempered hardness used by the roller shaft core is about half of it. 45 # steel is softer than the bearing steel, which implies that shaft wear is bound to occur when there is an improper fit.

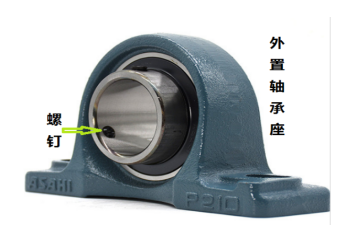

2. Presently, the measures to prevent shaft wear consist in coupling a set of external bearing screws. But for various reasons, the shaft grinding phenomenon still occurs:

a) Poor quality of bearing seat set screws, tooth slither, end wear phenomenon.

b) The bottom hole of the internal thread of the bearing seat is too large, the thread is loose, the fit with the screw is loose, and the screw is not tight.

c) During assembly, the screws are not tightened or the required tightening torque is not reached.

d) When the belt conveyor is running, there is a vibration that can cause the screws to loosen.

2. The gap between the shaft head and the external bearing seat is not appropriate.

When the set screw is loose, the size of the gap becomes one of the factors that causes shaft grinding. With the increase of the gap, the space for the movement of the shaft head increases and the trajectory of the roller becomes irregular and there is severe friction between the shaft head and the bearing steel.

So, how can we solve this problem?

The general idea is to abandon the set screw connection and use other connection methods, such as:

a) Eccentric locking connection

b) Tension locking connection

c) Interference fit coupling

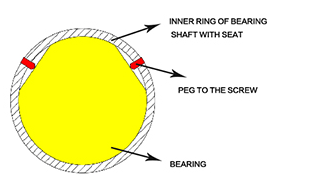

However, the solution given by Damon Industry is based on the innovation of the set screw connection selected by most manufacturers! What is it then? —— The force driven V-shape flat screws!

The force driven V-shape flat is not very different from the other types of connection:

1) Clients do not need to change their old habits and design (set screw connection), which eliminates some costs.

2) Clients can make use of the convenient installation / maintenance of the old set screw connection.

3) Even if the screw is loose, the end of the screw can get stuck in the position of the flat wire and it is not easy to detach it from the shaft, so as to avoid the corresponding friction between the shaft and the bearing.

There is no high cost, no long wait, no complicated installation and its maintenance doesn’t give you headaches. The force-driven V-shape flat of Damon Industry will give you a brand new experience. We believe in creating competitiveness for your logistics system!