English

中文

English

Europe

Welcome to Damon Industry Website

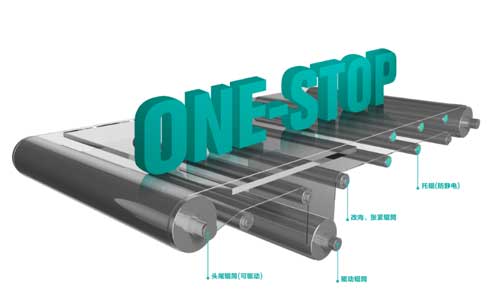

As we all know, the driving roller, the head and tail roller and the tensioning roller used in the belt conveyor need a lot of turning, so we are used to call them turning roller. It is precisely because that the need for a large amount of machining can provide greater flexibility, and there is no professional supplier in the market; Therefore, each belt conveyor manufacturer is used to independently design and process or outsourcing the manufacturing of rollers, and the roller is completely reduced to a processing part.

With the rapid development of logistics equipment industry, especially the rapid development of domestic express delivery industry, the demand for belt conveyor has increased substantially, so does the demand for the rollers. Due to the different needs of the different scenes, different design schemes and models are needed. Meanwhile, the expansion of the manufacturers and the alternation of the designers give birth to a large number of completely different but very close roller for belt conveyor in the market. As it is a processing part, the roller does not have such information as the model or code of industrial products, production time or batch, production supplier, etc., which brings a lot of troubles to both the belt conveyor manufacturer and the end user:

1. It takes a lot of work for customers to identify different rollers when receiving goods, so they need to measure and compare the rollers one by one with their drawings. At the same time, the receiving personnel should be equipped with professional skills to be able to identify drawings and accurately measure and judge.

2. In order to ensure normal warehouse management and accurate delivery, additional labels and more storage space are needed by the warehouse.

3. It is difficult to identify on the assembly site, and another setting and measurement are needed to ensure the roller is installed on the correct position on the conveyor, which greatly reduces efficiency and increases quality risk.

4. The later maintenance of the belt conveyor is very difficult. If the roller needs to be replaced, there is no specific model, specification and manufacturer, so the user may not be able to implement it quickly and accurately, and they need to repeatedly search for information and communicate with the equipment supplier for confirmation, resulting in extended or uncontrollable downtime.

Since Damon Industry began to provide customers with the roller for the belt conveyor, it has required itself with the standard of an industrial product, rather than just providing customers with a simple processing part according to the drawing. The marking of products is the most basic requirement of a standard industrial product.

Damon Industry provides marks on each roller of belt conveyor, which not only solves the problems mentioned above, but also reflects our responsibility and confidence in quality:

1. If there is a quality accident during the operation of the roller, with the specific model, specification, manufacturer and production time or batch, the real cause of the source can be traced, fundamentally avoiding similar problems in the future.

2. During the later maintenance of the belt conveyor, if the roller needs to be replaced, the customer can directly find the model and specification by checking our label, thus quickly and accurately carrying out the implementation without the repeated search of data or communication and confirmation of the equipment supplier. The normal and stable operation of the equipment can also be ensured, and the downtime can be controlled within the minimum range.

The belt roller of Damon Industry, the standard industrial product, has been in the well-known customers: SF Express, STO Express, ZTO Express, YT Express, Yunda, Jingdong, Cainiao Yizhan, Vipshop and other sorting and distribution centers. The stable quality of our products ensures the normal operation of customers' equipment.