English

中文

English

Europe

Welcome to Damon Industry Website

With the rapid development of E-commerce and express delivery, China's total express deliveries reached 50.5 billion in 2018, 9 times more than in 2012, ranking first in the world. In order to manage sorting and packaging efficiently and to calculate shipping costs accurately, it is necessary that the information on the package (dimension, weight and barcode) is processed automatically and uploaded to the central system in real time. The parcel sorting system that processes weighing, barcode scanning and volume measuring automatically is called DWS (short name).

Stable and efficient operations have an impact on the processing capability and efficiency of the downstream sorting system.

The belt conveyor pulley played the greatest role in testing the DWS system’s belt conveyor. If the belt conveyor pulley caused problems, both the roller conveyor and the DWS system wouldn’t be able to function properly; if the belt conveyor had small up and down circle movements, it could lead to vibrations of the belt conveyor and to the DWS not being able to measure dimension, weight and to scan the barcode of the package normally, in that way influencing efficiency of the whole sorting process.

Since the belt roller’s quality and performance could have a positive or a negative effect on the DWS system used by the express delivery supplier but also on the package sorting system, how could Damon industry provide a performant, high-quality roller pulley?

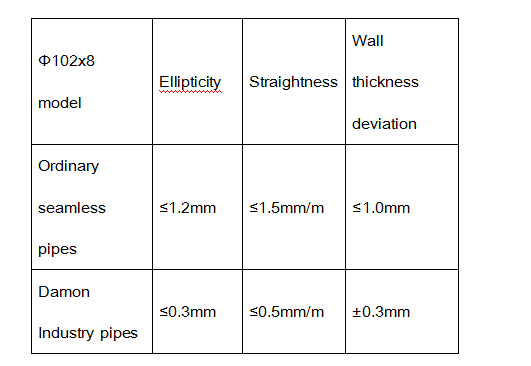

1. Good materials are the basis of good products. Damon Industry customized high-standard pipes for the outer tubes of the belt rollers. These pipes proved to be much more performant than the ordinary seamless pipes that are so present on the market.

2,Friction welding is employed to weld the axle center and the seal plate of the belt roller. This type of welding is commonly used in the aviation industry, so as to ensure high strength to the welding point, consistency to the batch and stability to the welded parts.

3,The conventional CNC lathe and boring equipment were upgraded, and all axes, outer tubes and inner holes of the tubes were processed by using one-time positioning and one-time clamping, so as to ensure good concentricity and a low circular run-out.

Damon Industry provides customers with a performant, high-quality belt conveyor pulley in which it invests professional equipment, a unique processing technology, exclusive custom-made materials and a strict quality control. As long as your belt conveyor is equipped with the belt roller manufactured by Damon Industry, you no longer need to worry about any malfunction and future problems. Up until now, Damon Industry has provided more than 6000 belt rollers for the DWS system.

Our company wants to provide customers with a stable, reliable DWS and package processing system, so clients can enjoy an amazing online shopping experience!