English

中文

English

Europe

Welcome to Damon Industry Website

[14:00 p.m. April 15, 2019, Shanghai, China] Zhejiang Damon Industrial Equipment Co., Ltd., one of the world-leading conveyor roller manufacturers, officially releasd “ZAM Pipe Roller” at stand N3B15 of LogiMAT China. A large number of clients came to the conference to witness this defining moment with Damon Industry.

Damon Industry is innovative to apply “ZAM”, an anti-rust and environment-friendly material, to the main material (steel pipes) of conveyor roller.

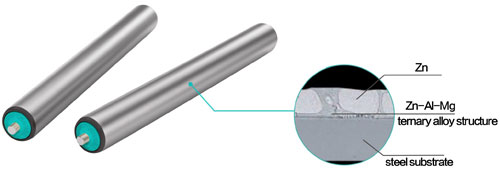

ZAM, the acronym of Zinc, Aluminum and Magnesium and abbreviation for “zinc, aluminum and magnesium ternary alloy coating”. There’s a kind of alveolate structural organization in the coating, so it possesses favorable corrosion resistance, rub resistance and adhesive force. Owing to its strong advantage in performance and environment-friendly galvanizing technology, ZAM pipes have gained popularity among and drawn the attention of the major industries.

Damon Industry is the first company to introduce “ZAM pipe” into roller industry in China, greatly enhancing the anti-rust capability of the rollers without worrying about the restrictions on electroplating equipment and environment, guaranteeing continuous delivery and creating value for our clients.

What exactly are the advantages of “ZAM Pipe Roller” of Damon Industry?

一、More favorable rust resistance of the surface, capable of coping with various humid and severe environments

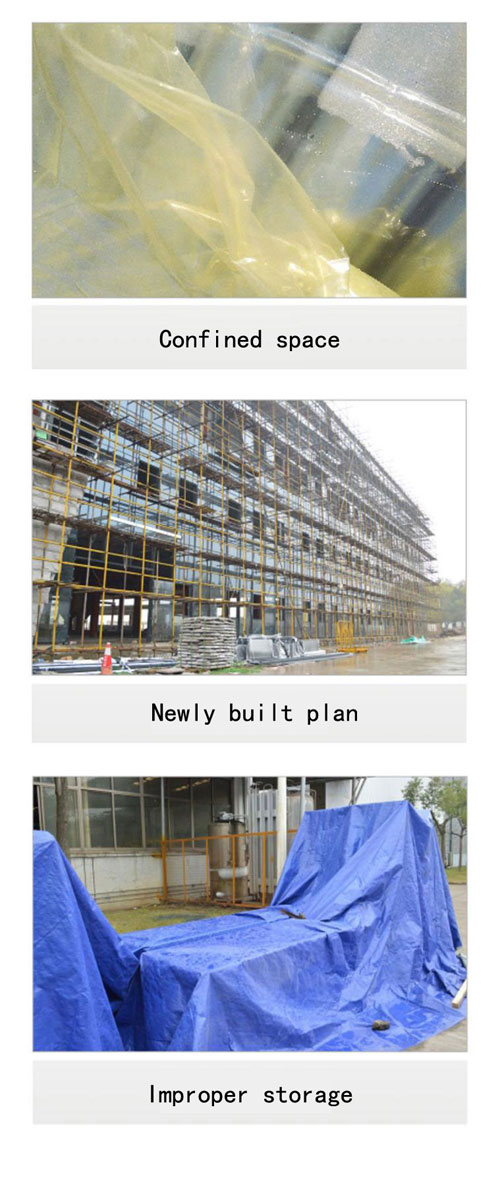

Have you encountered the following the circumstances where the roller may get rusted in your daily work? Stored in confined space, the roller may get rusted due to the condensation produced by the temperature difference between inside and outside; In the newly built plant to be perfected, the roller may get rusted due to the high humidity on the conveying equipment installation spot; Or the roller may get rusted since it is placed in humid environment before or after installation.

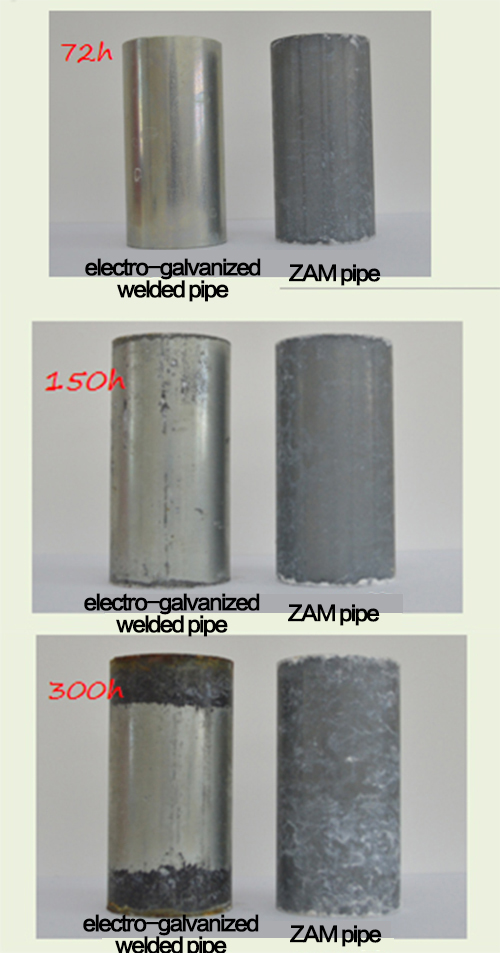

The super-strong corrosion resistance of ZAM pipe rollers manufactured by Damon Industry can solve the problem of rusting on the surface of rollers. The following is the comparison of salt spray test between ZAM pipe and electro-galvanized pipe.

According to the above data, ZAM rollers possess very strong corrosion resistance, capable of coping with various humid and severe environments easily.

二、 Dispensing with re-galvanization and guaranteeing continuous delivery

In the project delivery, are you still concerned about the delay that may be caused by the abnormal condition of galvanization?

The ordinary welded pipes need to be outsourced for electrophoresis and galvanization after being received. The products, in most cases, cannot be delivered on time restricted by the status of electroplating equipment and environmental protection policy. While ZAM pipes, already applied with ZAM coating, don’t have to be outsourced for galvanization and can guarantee the continuous delivery of products in the premise of keep environment-friendly.

In LogiMAT China exhibition, Damon Industry shall officially release ZAM roller. Welcome to Stand 3B15, Damon Industry, for visit and guidance.