English

中文

English

Europe

Welcome to Damon Industry Website

As implied by its name, accumulation conveyor rollers are mainly used for “accumulation” and “release”. By means of accumulation conveyor rollers, goods can be transported forward and can be temporarily stored on the conveying line, while the driving engine and elements are still running and the load is gradually increasing. As a result, the accumulation conveyor became very popular in various industries.

At the moment, besides classic accumulation conveyors, Damon Industry operates digitally electric rollers that can fulfill the accumulation function. As a result, we can divide rollers in two categories, based on their accumulation technology:

1. Zero pressure accumulation (by using electric rollers)

2. Friction accumulation (by using rubber-encapsulated, adjustable accumulating rollers)

Case 1 - Zero pressure accumulation

Scenario and questions: After being shaped, tyres need to be transported by accumulating rollers so as to be able to get in the next phase. If at this point, when the rubber is not fully solid tyres collide, they can stick together and also, their surfaces can suffer damage.

Solution: Using Damon Industry electric roller’s function, the zero pressure accumulation, goods are separated when accumulated or released. All of this by using a common accumulating roller.

Case 2 - Friction accumulation (by using rubber-encapsulated accumulating rollers)

Scenario and questions: After the blocking mechanism placed in the middle of the accumulating line was removed, goods (card boxes) couldn’t move forward. Investigations showed that a slightly tilted plastic bar was installed on one side of the conveyor, for the purpose of guiding the goods to the push rod. Because of the bar, resistance against advancing goods increased up to the point when the bar became a blocking mechanism. Moreover, the machine had to be paid in full in 3 days and it was too late to make changes.

Solution: Customers used rubber-encapsulated accumulating rollers. By increasing the transmission ring’s performance, some of the accumulating rollers were transformed into forced rollers and the problem was solved the next day.

Case 3 - Friction accumulation (by using adjustable accumulating rollers)

Scenario and questions: In order to increase efficiency, customers planned to transport multiple boxes at once, by stacking them. The total weight was of 300 kg and their accumulating rollers couldn’t satisfy this requirement.

Solution: Damon Industry provided adjustable accumulating rollers for this customer, so that the original accumulation capacity tripled. Not only that the customer was able to satisfy the new requirements, but he also saved a lot of time.

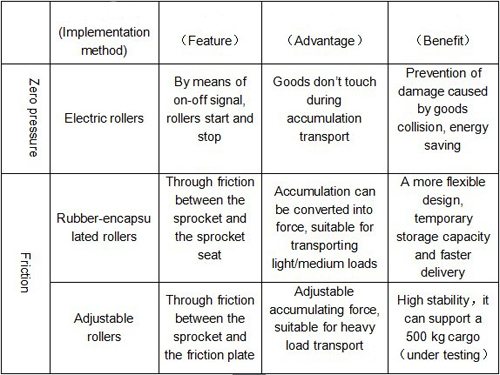

In order to help readers understand “roller accumulation” better, we have enlisted the principles and advantages of each of the accumulation technologies in the following table:

Up until now, Damon Industry has delivered over 300,000 rollers for various kinds of accumulation conveyor and participated to hundreds of projects, covering more than 10 industries such as logistics, e-commerce, rubber, electronics, medicine, building materials, etc.

Following hard work and continuous innovation, Damon Industry has been able to provide good quality products and to be a constant support for its clients in matters of variety and flexibility.

We truly hope that by reading this article, customers will be able to choose the right accumulation technology!