English

中文

English

Europe

Welcome to Damon Industry Website

In recent years, synchronous pulley rollers have become more and more popular in the markets due to the precise positioning transportation and high transportation efficiency so that the customer demands are growing.

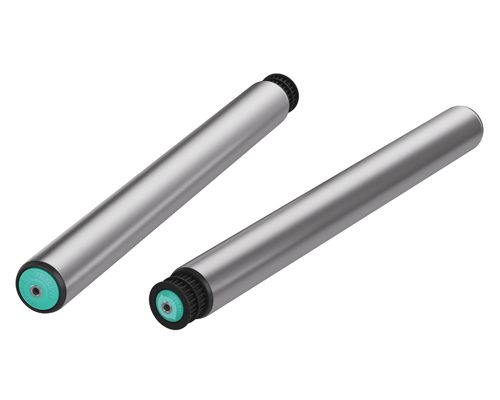

Synchronous pulley rollers, featured with more powerful transmission capacity, can be applicable to medium-and-heavy-load transportation. It is featured with compact structure, simple design and tension-free. It can be applied to dust-free rooms and other environment with much strict requirements matched with PU synchronous belts. Compared with traditional belt drive, it can work under certain severe environmental conditions and is featured with easy maintenance and lubrication-free property due to the property of anti-slip (hydrophilia). Compared with the steel-made marketable synchronous pulley, what kinds of advantages do Damon 2280 synchronous pulley rollers have?

1. Low cost

Traditional synchronous pulley rollers together with synchronous pulley belong to metal processing parts, meanwhile, it is necessary to weld ribs at both sides of pulley for preventing off-tracking, all of which result in high cost; On the contrast, Damon 2280 synchronous pulley rollers are made of high-quality polyamide composites and shaped by injection molding, which can significantly reduce the purchasing costs of customers under the premise of keeping the same performance.

2. Short delivery period

For traditional synchronous pulley rollers, in addition to the more time required for metal processing of synchronous pulley, there is also another procedure for welding the pulley with the shell; On the contrast, Damon 2280 synchronous pulley rollers are shaped by batch injection molding, with the rollers being almost modular assembly, press fitting and sealing for shell and pulley, free from welding, thus simplifying the assembly procedures.

3. Low noise

Compared with traditional steel synchronous pulley, Damon 2280 synchronous pulley rollers, equipped with high-performance polyamide sprocket roller as the drive element, greatly reduces the running noise.

4 More applicable to humid environment

The pulley of traditional synchronous pulley rollers is made of steel, with the surface being galvanized or black, but it cannot survive in the water environment for a long run considering the certain anti-corrosion capacity. Damon 2280 synchronous pulley is made of high-quality polyamide composites and shaped by injection molding, which can work normally even under the water environment for a long run.

Till now, Damon 2280 series have been put into the market for half a year, with high praise. Damon Industry will continue to devote more energy to achieve the innovation and create more value to customers.