English

中文

English

Europe

Welcome to Damon Industry Website

At present, the papermaking industry is affected by environmental protection, supply-side reforms, elimination of outdated production capacity, rising price of raw materials and other factors, which has caused significant impact on the cost of papermaking companies. The improvement of production efficiency and the optimization of comprehensive costs have become imminent.

Continuous large-scale production of papermaking companies focuses on stable operation and maintenance of the equipment. The paperboard conveyed by the processing section has a width of 1,500 mm, and the goods weigh is up to tons. The most important thing is the smooth convey of the power roller conveyor, of which the key component is the roller.

Due to the increasing competition and homogenization of the industry, the quality and performance levels of the power roller conveyors are not in the same level, and the quality of spare parts is not qualified. In the process of use, there is often a large jump affecting the smooth convey of the cardboard, resulting in cardboard off-tracking and looseness, etc., which directly increases the scrap rate of the paperboard; due to the fact that mandrel machining process is not accurate, there are inter thread eccentricity, lack of elasticity and shaft fracture, etc., resulting rollers cannot be installed or normal used, which leads to project delays, and improves the probability for follow-up suspension, repair and maintenance of the equipment; due to poor surface treatment of rollers, scratches, spotting and uneven galvanization, etc., the surface damage of the bottom of the cardboard will be produced directly, for which rework or replacement treatment is needed; In addition, in the process of use, there will be noises or jamming of the rollers, which will interfere with the work of field workers and irregular equipment overhaul. These disturbing problems not only seriously affect the normal use of the equipment, but also consume a lot of energy and material resources of companies.

For more than about 20 years, Damon Industry has been dedicated to the research and application of customized roller services, provision of stable and innovative roller products to help industry users improve operational efficiency and reduce logistics costs. The above-mentioned problems are easily solved:

1: Roller products are made of high-quality raw materials, and some key indicators are customized according to more stringent requirements, such as roundness≤0.25 mm, wall thickness deviation≤8% and straightness≤0.5 mm/m, etc., enabling the roller to be of better circular runout performance superior to JB/T7012-2008 to ensure the stability and reliability of cardboard convey;

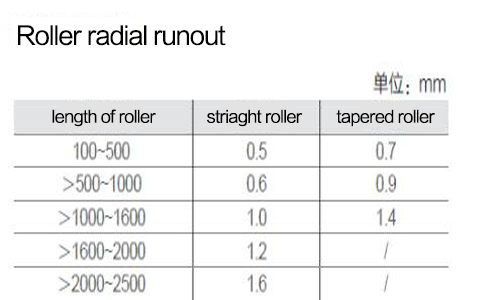

Radial runout of rollers :

2: Automatic servo cutting machine is used to ensure the accuracy of the cutting size, and the drilling-tapping integrated machine with automatic feeding and chamfering is used to machine the mandrel to ensure the concentricity of the internal thread at both ends, and the position-and-size fixing press equipment is used to ensure the fixed punching ear of the mandrel, etc. With the high standards and strict requirements of various processes, the quality of the finished products is ultimately improved to ensure the smooth installation and operation of the rollers at the project site to reduce labor intensity of the workers and overhaul, maintenance and reservation, etc. of the user’s equipment;

3: The galvanization of roller surface meets ROSH environmental protection requirements. It adopts special sealing process, which is more resistant to corrosion, and the salt spray test performance is significantly improved, which ensures consistency of roller surface, reduces surface light pollution, and the one-time convey passing rate of the cargo cardboard can be ensured at the same time;

4: According to characteristics of the rollers, the clearance, lubrication and sealing methods are specified. The patented bearing which is more suitable for roller application has been developed as patent together with bearing manufacturers, which is maintenance-free during the service life and the stability and durability of the conveying equipment have reached the highest standards. With all these means, the smooth running of the roller itself is ensured, and the failure rate of the equipment is directly reduced or eliminated.

At present, Damon Industry's rollershave been widely applied in the paper industry, including Chenming, Bohui, Hengyuan Zhonghui and other projects. With the deepening of Industry 4.0 and the rapid development of industrial intelligent manufacturing, Damon Industry’s electric roller has been applied to the paper industry at present. In the future, with the guarantee of high-quality rollers, we are willing to bring the experience of other conveying industries to the papermaking industry, and go hand in hand with all users!