English

中文

English

Europe

Welcome to Damon Industry Website

About twenty years, Damon Industry has finished the successful change from the small enterprise to a strong one. It has been focusing on the roller manufacturing, and seeking to become the most influential supplier and service provider in the field of core components of global logistics equipment. In 2004, Damon Industry was involved in R&D and manufacturing of conveying roller. It is the Chinese pioneer in standard production of conveying roller. For twenty years, Damon Industry, has believed that the "small roller is worth being researched". We have always focused on the R&D and manufacturing of the conveying roller, creating each roller with excellence. In order to make every conveyor line of roller support the application of terminal products perfectly, Damon Industry has taken quality as the measurement of material and manufacturing at the beginning of roller production.

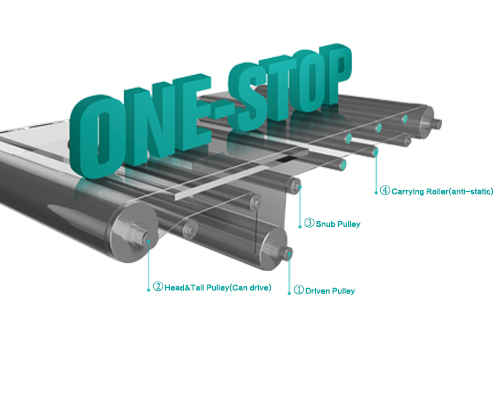

We are inheriting the glory of the past, and continuing to innovate in the future. In the logistics transportation industry, the orders are picked by parcel. There is a demand for transmission of soft bags. The application of belt conveyor will play a great role. Whether the belt conveyor is stable and reliable or not is very important in the transmission process. But at present, the quality and performance of belt conveyor are uneven in the market. The belt roller is the core of the belt conveyor. The quality problem of the driving roller and the head and tail roller are outstanding. The common problems are: (1) For the belt roller, the sealing-off of cylinder shell, sealing plate welding, the spindle head and the sealing plate often occurs during the operation, which leads to shut down. (2) The roller shaft design structure leads to the non-operation of the belt conveyor, and it needs to be replaced by the driving device to improve the driving force; due to the problem of the raw material quality and machining accuracy of the roller, intermittent belt deviation and insufficient tension may occur, which requires maintenance of equipment time to time; the mismatch between the roller type selection and the actual application requirements may cause the broken shaft, abnormal sound, etc. The above two disturbing problems have not been solved fundamentally in the industry and the situation has caused a great impact on the normal use of equipment, which directly brings about serious economic losses and damages of market reputation.

For three years, Damon Industry has created a new solution and standard for belt roller, and strived to solve the problems between the traditional backward processing technology and high performance requirements fundamentally.

First, warm friction welding--change the traditional welding technique to device welding (Patent No. ZL201520947264.8). The welding process is automatically controlled by the device, making the contact surface material of the head and the sealing plate, the cylinder shell and the sealing plate fully be integrated into one part. The welding fusion intensity of the contact surface has been far higher than that of the parent material, which fundamentally eliminates the hidden trouble of sealing-off!

Second, structural innovation--a brand new design organization, has greatly reduced the weight of the roller. The simple structure and strong strength have reduced the load of the driving device, and made the belt conveyor operation more easily and flexibly. Damon Industry has adhered to roller products for about twenty years. It stands at the new height of the belt roller of belt conveyor manufacturing again by the pioneering craftsmanship spirit. This series of optimization and improvement of belt roller can provide strong support to ensure the stable operation of the equipment.

The friction welding belt roller of Damon Industry has been used in the sorting center and express distribution center of Jingdong, Suning, VIP.COM and other well-known electricity suppliers. It ensures the stable operation of belt conveying equipment of the customer's logistics system.

This year, we are offering full system roller product solutions. Meanwhile, our service objects are becoming more and more widely. Multi-industry, multi-field and multi-channel sales promotion activities are also being launched in an orderly way.For example, products exchange of Damon Industry: in May 2017, Damon Industry invited more than 40 well-known customers and technical personnel to attend the product exchange activity successfully held in Huzhou City, on the south bank of Taihu Lake. It provided a comprehensive introduction and information exchange of the conveying roller, 24V DC electric roller products and application of Damon Industry.

Damon Industry, focusing on roller for about 20 years, has been imitated but never been surpassed. Conveying roller seems like a very simple product, with low threshold of manufacturing. The products have been imitated, resulting in uneven quality in the market. Damon Industry is of advanced equipment, strict quality management, perfect internal control of paperless and systematic process, which ensures our products can exceed the products at the domestic level of technology. The satisfactory service has no starting point, nor ending point. Damon Industry always provides customers with conveying rollers of high quality, which makes the customers at ease and assured. Conveying roller of high quality not only can ensure the long-term efficient operation of transmission equipment, but also reduce the input of customer service. It is conducive to establishing the corporate image, enhancing the competitiveness of the company. Staff of Damon Industry are willing to work with you in joint hands to create a beautiful tomorrow.