English

中文

English

Europe

Welcome to Damon Industry Website

-- Interview General Manager CaiYongzhen of Damon Industry

Zhejiang Damon Industrial Equipment Co., Ltd. (hereinafter referred to as "Damon Industry") is a manufacturing enterprise focusing on conveyor rollers. This year marks the about 20th anniversary of Damon Industry. During the two decades, great progress has been made in Chinese logistics industry and Damon Industry also has become a worldly famous manufacturer and technical service provider of logistical conveying components (conveyor rollers).

The rapid development of Chinese logistics industry is inseparable from the upgrading and progress of relevant equipment. The conveyor roller is a kind of core component widely used for production lines, material handling systems and material sorting systems etc. Such small component can affect the operating efficiency of the logistic system. Damon Industry has specialized in design, research, development and production of conveyor rollers for two decades, gradually improving technology and stability of quality of such product to make it become one of the basic components of equipment production line, material handling systems and material sorting systems of world famous enterprises and logistics enterprises. Damon Industry makes use of conveyor rollers which are seemed as little thing to promote huge market of roller with wide usage and drive progress of Chinese logistics industry. It is said that the roller manufacture becomes a grand cause. With two decades of gradual progress and growth, what is the special charm of conveyor rollers of Damon Industry? What are the secrets for success of Damon Industry? Therefore, we interviewed the General Manager - Ms. CaiYongzhen of Damon Industry.

Product - Past and present conveyor roller career of Damon Industry

Story of roller

Reporter: how does Damon Industry determine conveyor roller as its core item of career?

CaiYongzhen:The current management of Damon Industry is its second generation of management team and the first team is the entrepreneur team taking Zhuo Xu (the president of Damon Industry) as the core. About 25 years ago, President Zhuo as the founder of enterprise accessed conveyor roller in Japan. He was surprised to find that there was a different roller production method in Japan from that in China. Chinese rollers were manufactured according to the standards of coal industry (the coal carrier roller), which were too heavy and costly. But Japanese conveyor rollers were light and handy. Such light conveyor rollers were made by using stamping bearings and processed by using standard pipes and President Zhuo wanted to introduce the conveyor roller production method into China. But the Chinese logistics industry still stayed in the era of forklift at that time and few conveyor lines were used so that the production technology of conveyor rollers was backward. At this stage, President Zhuo visited and investigated domestic and foreign conditions, learned advanced production technology of conveyor rollers and got the assistance of advanced European manufacturers, Malaysian experts and domestic famous manufactures. In this case, Damon Industry preliminarily obtained production technology of conveyor rollers. From the point of current views, the production technology of Damon Industry at that time was still primitive, but such technology was fully different from that of mine carrier rollers. The first leading team of Damon Industry has completed the process from developing from nothing with respect to conveyor rollers.

The current management team took over the company after 2000. Our responsibility is to make Damon Industry sustainable. Although Damon Industry already obtained the production technology of conveying roller primitively, there are more and more enterprises that can produce conveyor rollers and how does Damon Industry stand out from the numerous manufactures? This is what we need to consider. After taking over management, we first reorganize the company from all aspects such as management and personnel. We must first rationalize the company's system to ensure the stability of product quality and introduce effective talents to lay the foundation for the upgrading of the technology. We identified a concept at the time: we must continue to enhance the roller quality of Damon Industry, should not be content with low quality and low price products, which can make the company realize a sustainable development. Roller is the core component of logistics equipment and is crucial to the overall enhancement of the conveying and sorting system. Only if the roller has stable quality and stable operation, the speed and efficiency of the entire system can be lifted stably.

Continuous development of roller business

Reporter: in the past two years, Damon Industry has launched a number of new products and new technologies. Please introduce them.

CaiYongzhen: Although conveying roller is the basic component of a logistics system, its manufacturing processes and product performance has continued to improve with the changing needs of our customers, and Damon Industry has been keeping pace with this trend. As early as 2012, Damon Industry and Japan's KYOWA began a strategic cooperation, fully conducting micro-electric roller business in Chinese market. By virtue of reliable product quality and professional service, Damon Industry has won a good reputation and good performance in the industry in just a few years.

Our R & D department never stop their step on the road of innovation. With the burst in logistical equipment industry, more and more customers had higher requirements on heavy transporting equipment, for instance, the roller needs to have a stronger structure, more powerful torque output, and also better adjustments in control module. Based on things like these, Damon Industry brought out a masterpiece —— DC24V Pallet Handing MDR debuting in the CeMAT AISA Fair in 2015. SENERGY, this new-generation intelligent Pulseroller may just appear to be a little bit thicker, but there are a lot of improvements and innovations inside. Which could be listed as: safe DC24V voltage; simple design, space saving and quick installation; large torque, be able to propel a wooden pallet weighing about 1,400 kg; soft start/stop and speed adjusting functions, make sure it runs safely and smoothly; also a good choice when there is a restriction on space as it could solve the transporting issue. If we combine the roller with AGV or transplanter, mounting the original motor inside the roller instead of leaving the motor in a separate room like it used to be, and then there is a lot of space saved.

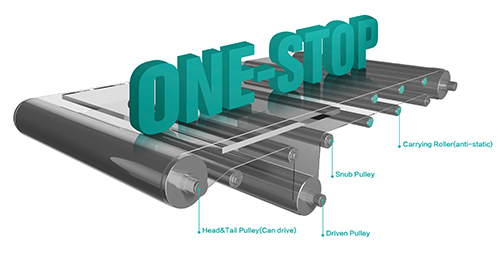

Thanks to the burst in E-commerce and express industry over the past two years, the market has a great demand for the belt conveyors. The supporting carrier rollers of belt conveyors have become a new growth point for Damon Industry. Damon Industry always emphasizes that the basic is fundamental, then comes the development. Before we took over the manufacturing line of belt conveyor pulley, 6 to 7 months were spent for sorting the technological process, to make sure that we are prepared for the standardized ERP system and the quality control system, then gradually starting the producing. So that there is a solid guarantee when Damon Industry brings out its professional product line of belt conveyor pulley, they will always carry on the high strength of wielding and precision of processing.

Production - from manufacturing to "manufacturing with wisdom"

Reporter: conveying roller of Damon Industry has a stable quality and good reputation, which has a close relationship with the strong manufacturing capacity of Damon Industry. Could you please introduce how Damon Industry continues to improve its manufacturing technology and capabilities?

CaiYongzhen:One original and important reason why the production process of Damon Industry can continue to be improved is that they force production with problems. In the event of a problem with our product, the company asks not only to passively solve the problem, but to find out the underlying causes and solve the problems behind the problem. Such a process will promote the overall enhancement of the manufacturing capability of the company without any apparent cover. Forcing themselves into upgrading their own crafts and processes with questions is a painful transformation process for enterprises. After our continuous improvement, our rollers have improved from bearing 500,000 pallets to 700,000 pallets each time, and now we are able to meet the requirement of bearing 1,000,000 pallets time. These are the data tested by the customers.

Damon Industry is also committed to promoting the continuous progress of conveying roller production technique. For example, Damon Industry has promoted changes and advances in roller surface treatment processes. The original roller surface treatment process in China is hot-rolled, and then polished. But such a process is a waste of resources. Later Damon Industry first uses directly galvanized pipe materials to work as a roller, thus eliminating the need for polishing process. However, scratches will be easily generated on the galvanized pipes in the delivery of the product, affecting the appearance, and there is more serious pollution in the galvanized process, which in turn urges Damon Industry to study more environmental process. Currently, Damon Industry attempts to manufacture conveyor rollers by using galvanized pipes as the base material. We hope to make roller manufacturing process easier and more environmentally friendly. Previous welding rollers had a complex process. Now we have improved the process, making it easier and the whole roller more lightweight and strong. Besides, the biggest problem with the belt roller is the shaft breaking. We solved this problem by introducing a friction-welded roller, which reduces the weight of the product. For us, the improvement of the production process includes the promotion of the change of the product structure, process and equipment, which are all the keys to make the production simpler, more reliable and more efficient as well. Nowadays, it is very difficult for us to get the solutions to these problems by imitation and reference, so we need our own exploration and innovation. The important principle therein is: customer's demand is our research direction. With this major principle, major directional errors will not occur in our exploration.

Reporter: for customers, they want to get their products not only with good quality, but also with a good price/performance ratio. How does Damon Industry meet customers' needs like this?

CaiYongzhen:Yes, it's true that if a product is expensive and price/performance ratio is not good, no matter how fine it is, customers will stay away from it, so it is difficult to really achieve the product value. Damon Industry is in the forefront of promoting the manufacturing process of conveying roller, requiring constant trying and trial and error, which leads to high cost. In this case, what needs to be done to reduce costs to meet customer needs? According to the Damon's experience in technology, there are the following points:

Firstly, pay attention to details and process optimization. At present, there is no much space for the conveying roller products to reduce the costs in the material, and more cost reduction exists in the optimization process links. For example, in the premise of ensuring product quality, the original 4 processes can be optimized to 2 processes or even 1 process, which can significantly reduce the cost of production. Simplification of both the structure and the process is what we pursue. If we can do it and make some breakthrough, our production superiority will naturally be manifested. We also need to pay attention to tapping the potential of energy saving and improving efficiency in the production details. Damon Industry produces about 50,000 products annually, and if a small innovation in details can save a little of cost, the cumulative effect of the year is considerable. Moreover, the optimization of such details is sustainably mined. Therefore, as the production managers, we think that there is still room for optimization of production, the manufacturing has a brilliant future.

Secondly, the use of advanced information management systems can enhance the operational efficiency of the entire production. At present, Damon Industry Company has completed the overall ERP system construction. At present, some of our peers still continue the traditional practices in production, but it has been difficult to adapt to the needs of modern production without a complete ERP system. For example, most of the conveyor rollers are in custom production. Under the traditional mode of production, the product design and drawings need to be manually finished by engineers, which is costly, slow and easy to go wrong during production and circularization. The ERP system that we set up has already achieved that the design drawings are finished in the computer, which has greatly promoted our production efficiency, and reduced the production cost. And now we are still in the level of automation to promote the production links. We believe, as the integration between automation equipment and advanced production information system is getting better and better, we will show greater effectiveness in production and manufacturing links in the next few years, which will increase per capita output, so that we will continue to maintain a strong competitive edge in the production.

Thirdly, we should consider reducing costs and increasing efficiency during the design links. Sometimes customers have unreasonable surplus in the design, when communicating with customers; we will advise the customers to provide more appropriate and more economical solutions, more cost-effective products. How to make the product structure easier from the perspective of the design. The simpler the product structure is, the simpler the processing will become, which reflects the strength and value of design. For example, now we are trying to make a breakthrough by studying and advancing replace the steel with plastics. As environmental requirements are getting higher and higher, we would wonder if there are better materials and better processing methods to solve customer needs. This plan is still going on, which we still need to continue. The general principle is that our products are designed to increase values for our customers, or our work does not make any sense.

Reporter: what would Damon Industry understand and do for the trend from manufacturing to "manufacturing with wisdom"?

CaiYongzhen:In my understanding, the process from manufacturing to manufacturing with wisdom is how to combine the software and the hardware. Taking Damon Industry as an example: software means our ERP system and APP system. We have started to develop these two systems since 2009. Today, we have made the breakthrough in entire information chain from the client's mobile phone client to the mobile client. The entire production information is passed through this closed-loop system, which helps in avoiding human errors to the greatest extent. Damon Industry has completed more than 13,000 orders this year, as we all know, the production organization is very complex for completing so much the volume of orders. The advanced information systems can ensure that no mistake will happen to the entire process. In our production site, each station has a terminal information display, workers will see the daily work plan on the job every day; after the workers complete these work plans and write off the work tasks, the system automatically arranges the follow-up work plan to the next process flow.

Hardware refers to the advanced manufacturing equipment. There is a process optimization work in the production process, that is, how to rationally allocate, optimize, and reduce processes, and pursue the higher productivity, which requires the process for gradual accumulation of experience. In the process of manufacturing products, we need to avoid a situation that a piece of equipment can be used to complete the whole product but the processes still need splitting, so we can make full use of equipment production capacity; to minimize the small process, so that the small process can be completed in a piece of equipment, in order to solve the work of a lot of specific processes, small working processes, a lot of equipment is customized and developed by Damon Industry, which is an important point of our optimization of production. In addition, we will pay attention to the introduction of international advanced production equipment. For example, Germany's RSA automatic cutting equipment, this equipment is very expensive, but can bring: efficiency improvement, quality stability, easier work of staff work. Automation is easy in one process, how to automate the entire production process and use the automation to improve efficiency need the overall concept, which is the focus of our current thinking. At present, in the bottleneck process, for example, in some equipment aspects, we consider using manipulators, automatic assembly, automatic detection, and automatic data transmission.

To rationally think smart manufacturing, these attempts are not just for show. We must always make clear about the purposes of automation and smart production: firstly, to increase the per capita production capacity; secondly, to improve the production environment for front-line staff so that they can work more comfortably and get protection Information investment, APP development, information systems are controlled throughout the entire process, with no blind spot for the customers to know of them, which are the innovations of Damon Industry.

Brand: to create a touch of bright green in the logistics industry with using products and services

Reporter: with the development of Damon Industry, your company's brand is accepted by increasing people. Could you introduce your company's work on brand building?

CaiYongzhen:In the process of Damon Industry from small scale to large scale, from the weak to the strong, we have been committed to producing high-quality products, but also sought to establish our own unique image, and independent valuable and influential brand. Originally, all Damon Industry's roller end caps were yellow. In 2006, we wanted to switch it to Damon Green. Green is the color appreciated by the groups in Damon Industry, represents the vitality, environmental protection and many other positive meanings. But then the image switch did not succeed, because the customers didn't recognize and understand our philosophy, leading us to switch back to yellow. This failure made us realize that the establishment of the brand needs its own strength to support. Since then, Damon Industry has been concentrating on making products and providing services on a firm footing.

In May 2015, we re-enabled "Damon Green" to create a new brand image. The switching of this image went very smoothly, and up to now, we have believed that the establishment of this new image was successful and the result was beyond our expectations. There are two indicators for evidence: firstly, in the year when the new product image was released, our sales performance was not affected but improved. The second point is more important that most customers still recognize our practices and actions.

We believe that the recognition of customers is the most important, which is also the most important value for Damon Industry to establish its brand. With support from our customers, our new image can be established, our brand can be recognized. In order to better serve our customers, Damon Industry has been working hard.

Taking APP of Damon Industry as an example, this project is designed to better serve our customers to a large extent. In the past, selecting the products and tracking the progress of inquiries orders need to call, send e-mail, etc. for our customers, leading to lower work efficiency. In May 2016, Damon Industry introduced the first App in the industry, which allows customers to make product type selections, download drawings and samples, and track order progress anytime and anywhere by just moving their fingers, greatly enhancing each other's work effectiveness. This easy-to-use APP software has been popular among the industry since its launch, and has been downloaded and used by more than 1,500 customers and has been unanimously approved by the market. However, Damon Industry did not stop the pace of improvement. Over the past year, the Marketing Department of Damon Industry has taken the lead in organizing a lot of demand research for the phase I users, completely upgraded and revised APP with addition of invoice progress query, electric roller type selection, belt roller inquiry, industry application case and other new functions, in hope of to providing customers with more comprehensive and better service. Currently, the latest version of Damon Industry APP has added a lot of useful features, including: 1. Product type selection support, newly added electrical roller type selection functions; 2. Product detail inquiry and newly added belt roller product information; 3. Order details inquiry, newly added billing progress and invoice logistics information; at the later phase, we will also launch online downloading functions of packing details of goods, roller testing forms and other functions.

Damon Industry has always followed the needs of its customers in the service and continued to improve the services. We organize product exchange sessions every year to explain the type selection of products, typical types of delivery, typical application occasions and precautions and other contents to our technical staff to assist in enhancing the professional competence of our customers. With rapid development of e-commerce, express delivery, warehousing logistics, factory automation and other markets in recent years, the existing professional and technical personnel have become scarcer in the industry, especially experienced professional engineering technicians. Many new technicians have joined the industry, needing professional training to be professional technicians as soon as possible, and existing engineers also want comprehensive training in order to be able to make more professional and excellent roller conveying schemes. For this purpose, Damon Industry invited more than 40 well-known customer technical staff in May of this year, held product exchange service activities in Huzhou City, the south coast of Taihu Lake successfully for a comprehensive introduction and exchange of conveyor rollers, DC 24V electric roller products and applications of Damon Industry.

After the product exchange activities, they were praised by the well-known customers who expressed that their professional ability has been well improved: 1. The new engineers have received professional training, to have roller type selection ability greatly improved, saving internal teaching and training time and efforts of customers. 2. The comprehensive training of the application of different rollers can provide better roller solutions for the needs of end users. 3. With small software for electric roller type selection, we quickly become a roller type selection expert! 4. Professionalism of the roller type selection has been improved, so more attention can be paid to the core business of equipment and system integration, to ensure better success of equipment and conveying system. The participating customers were very satisfied with this event and all agreed that Damon Industry would hold more product exchange activities in the future and further extend its application to the intelligent transportation of electric rollers.

Market - go to the world from Huzhou

Reporter: in recent years, Damon Industry has been active in the global market layout. Please talk about the latest progress of globalization of Damon Industry. What kind of change did this job bring to Damon Industry?

CaiYongzhen:Damon Industry business originally started from the internationalization. In development process of the cause of Damon Industry, we start from the trade, overseas factories to independent production of our overseas factories, cooperation with overseas partners with continuous expansion in business. In recent years, Damon Industry has indeed continued to advance in terms of globalization. July 2011, the factory of Damon Industry in Australia was established; in 2016, the factory of Damon Industry in Romania was officially put into operation; in addition, Damon Industry has its own partners in the United States, Japan, Malaysia, Indonesia and Singapore; Damon Industry also has their own agents in South Korea, Ukraine, Turkey and other places. In order to more conveniently provide services and technical support to customers all over the world, Damon Industry will continue to move forward and leave more footprints on the world map. At present, we have production bases in the United States, Romania and Australia. And we are still expanding, still with the model of trade + production of several strongholds. Overseas strongholds are for nearby service and rapid response. The mass production is still completed in our country, because the domestic production has the cost advantages. China's Belt and Road Initiative and the China Railway Express will also give China many opportunities and we will also consider exploring the opportunities. Although our overseas share is not high at the moment, on the other hand, it can be said that there is a great potential. We will make arrangements in advance, as overseas markets are very attractive to us.

Carrying the trust of customers, about 70% of the world's top 20 logistics system integrators have chosen the rollers of Damon Industry. Each year, more than 4,000,000 rollers of Damon Industry operate efficiently and stably on the 500 km conveying line with a full length of 5,000 km by connecting their ends. Damon Industry roller can be seen from the e-commerce courier to food and medicine, from the production line to the finished product warehouse storage, as well as from China to the world. In spite of producing small rollers, Damon Industry establishes an admirable logistics business with dedication to step into the future with glory.