English

中文

English

Europe

Welcome to Damon Industry Website

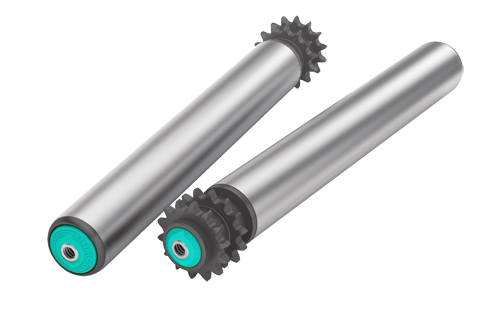

With the development of modern science and technology, automatic conveying equipment can be found in all walks of life. Among them, the conveyor roller has been widely used due to the large amount of continuous conveying, high reliability, easy maintenance and other advantages. The conveyor consisting of the plastic-steel chain wheel is a common roller conveying equipment, and chain wheels are made of polyamide materials (commonly known as the plastic-steel). Compared with traditional steel materials, it is featured with low running noise, self-lubricating & maintenance-free of sprockets and chains. At the same time, it can also be used in the wet place and the place requiring for disinfection and rinsing, which enables it to be the most widely used equipment especially in the industry of beverage packaging.

After the market research, it has been found that such kinds of products on the market have shortcomings, such as weak strength in the plastic sprocket, easy to ruin or rapid wear. The automatic conveyor roller line is a highly efficient and continuous delivery system, and replacing the damaged roller may result in the all stop of the entire system under continuous operation. The replacement of one roller may lead to this, and if more rollers are damaged, it will be more difficult to estimate the losses caused to end customers during the period of halt production and replacement.

In terms of this common problem, Damon Industry decides to explore more excellent plastic-steel materials. Plastic-steel is a kind of polyamide composite material, and different types of additives and slight changes in the application amount of additives will change the performance of the material. To this end, Damon Industry has visited a number of material suppliers, carefully screened a variety of different materials at home and abroad, and has found the ideal plastic-steel material through repeated conveying tests and creep experiments. The performance of such plastic-steel chain wheel has been greatly improved and enhanced, achieving stronger chain wheel and more wear-resistant sprockets.

However, the application of high-quality plastic-steel materials will boost the cost rise, and the problem is that who will bear such cost, we -the manufacturer or our clients? The team of Damon Industry never gives up, and after several times of research and discussion, Damon Industry technical workers find that improving the versatility of parts and complements of plastic-steel chain wheel products, that is, reducing types of parts and components and increasing the purchasing quantity of single parts, can effectively control costs. Damon Industry technical teams continuously focus on the work of research and development, and ultimately optimize the structure of such kind of products. The optimized structure not only achieves the versatility of roller parts and components, but also enables the roller to have a certain degree of versatility.

Take the plastic-steel double-chain driving roller and accumulating roller as an example, they are two different products with the same appearance but different functions.

Plastic-steel double-chain driving rollers are applicable for conveying light-and-middle-load goods; Plastic-steel double-chain accumulating rollers are mainly used for realizing the halted accumulation of lightly loaded goods on the conveyor line.

The general structure design integrates functions of these two products, and realizes different functions by adding or removing only one part (as called by Damon Industry: drive ring): it's the driving roller with the drive ring; it's the accumulating roller without the drive ring.

This improvement enhances the performance of the product, and achieves more wearable chain wheels and more robust sprockets through changing materials; while the optimization of the structure not only cuts the cost, but also improves the versatility of the product.

Up to now, the improved product has been put into market. Results of return visits show that the degree of satisfaction with improved products is high, chain wheels are tougher and more durable. In addition, the versatile structure makes it more flexible in terms of purchasing spare parts or on-site layout. The function switching of transmission and accumulation can be available just by adding and removing the drive ring, which is quite convenient and rapid.

Customers' recognition is an important driving force for Damon Induatry team to continue to move forward, and Damon Industry will also continue to carry out innovation to enable products to be upgraded and improved, and to create greater value for customers.